Realize high accuracy and longer tool life in ultra-high-speed drilling in machining center or turning machine where chip jamming is easy to occur.

- Even the traditional 3 times higher feed can also be stable processing by adopting good geometry of cutting edge and flutes for reducing thrust cutting force, chip breaking and evacuation.

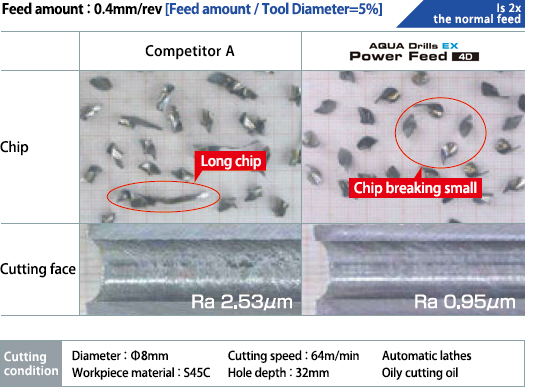

- Improved chip breaking performance and realized outstanding chip evacuation in work rotation turning machine as well.

- Even if it is stunning ultra-high-speed feed, but also can achieve long processing life, high-precision machining.

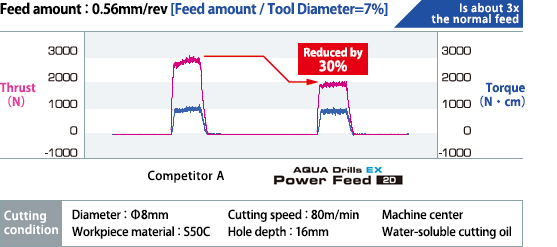

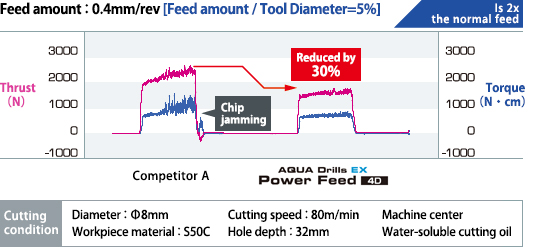

Significantly reduced thrust

Thrust is greatly reduced, so even in the 3× ultra-high-speed feed, chip removal is also very good

Cutting resistance of Power feed 2D

Cutting resistance of Power feed 4D

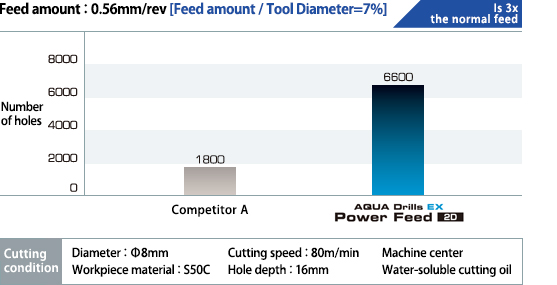

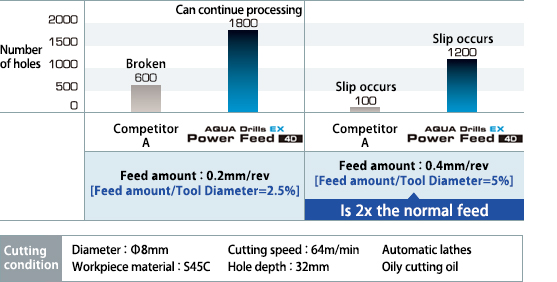

Ultra-high-speed feed also has a long tool life

When using a machining center for ultra-high-speed feed processing, Power feed drills have an overwhelming tool life. In addition, there is a stable performance in lathe machine which is liable to cause chip clogging.

Compare the tool life of using machining center

Compare the tool life of using lathe

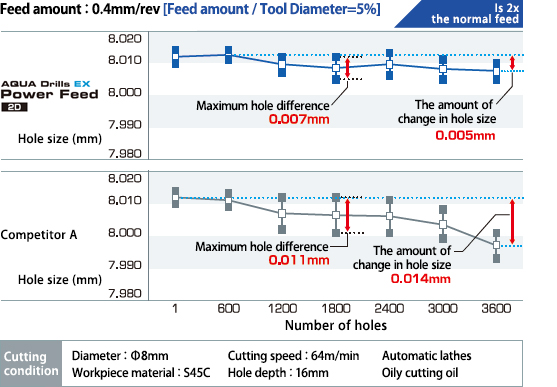

Ultra-high-speed feed machining is also highly accurate

Even in the case of high feed processing, the variation of the hole expansion amount is small, and a high-quality work surface can be obtained

Compare the hole accuracy of using lathe

Compare chip, machining surface of using lathe

Catalog Download

![]() Catalog No. 2235-3 AQUA Drills EX Power Feed (8 pages/4,930KB)

Catalog No. 2235-3 AQUA Drills EX Power Feed (8 pages/4,930KB)