Dry drilling of Aluminum

- DLC (Diamond Like Carbon) is an amorphous material with high hardness and low friction rate, and has similar character of Diamond. Application for drilling & milling in Aluminum Ultra high speed cutting in DRY !

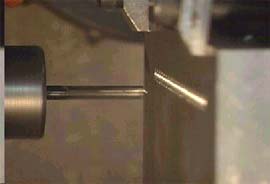

Excellent chip evacuation

- Trouble free drilling by unique flute geometry Stable & extra long tool life is realized by DLC film & its unique flute.

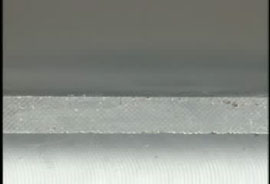

Construction of DLC

Thanks for newly developed DLC film having no built-up edge

| BALL | : SUJ2 | Disk | : Film/HSS (Ry0.2m) |

| Revolution | : 500min-1 | Over weight | : 100N dry |

| Machine | : CSEM Tribometer | ||

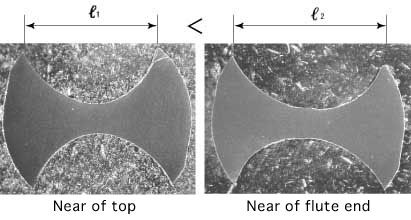

Adoption the flute which spread gradually (Pat.P)

Performance of Dry Drilling

|

|||||||||||||||

|

|

||||||||||||||

Performance of Wet Drilling

|

|

||||||||||||||||||