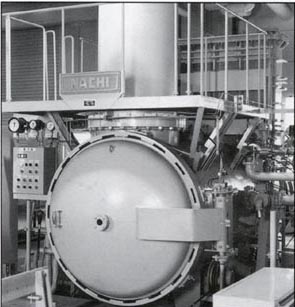

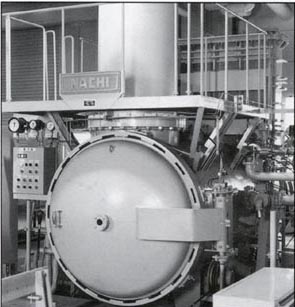

Model EVHP-182415 5 bar. pressured nitrogen gas rapid-quenching furnace for cutting tools of high speed tool steel.

VACUUM FURNACE provides:

- High Quality

- Excellent brightness and free from oxidation, carburising and decarburizing!

- Distortion-free and hours off for machining after heat treatment from bright surfaces!

- Long life for tools compared to other heat treatment processes!

- Wide applications for quenching, tempering, annealing.

|

Model |

Work Space (mm) |

Capacity |

||

|

Width |

Length | Height | ||

|

EVHF-182415 |

450 |

600 |

375 |

150kg |

|

EVHP-243614 |

600 |

900 |

350 |

300kg |

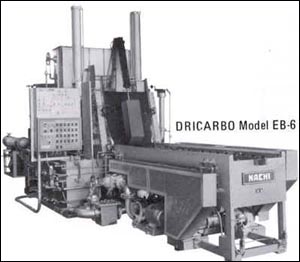

DRICARBO furnace are used for carburizing, carbonitriding, and bright quenching ferrous alloys for increased surface hardness wear resistance and fatigue strength for example Bolts, Nuts, Screws, Automative parts, Machine parts, Hand tools and etc. DRICARBO process has special vapered fluid supplied into the furnace to provide necessary atmosphere without the additional atmosphere gas generator.

Box Type

|

Model |

Work Space (mm) |

Capacity |

||

|

Width |

Length |

Height |

||

|

EB-6 |

600 |

900 |

450 |

350 kg |

|

EB-10 |

750 |

1200 |

600 |

800 kg |

DRINITE furnaces are used to impart wear resistant, fatigue resistant, corrosion resistant and seizure resistant characteristic for ferrous alloys.

DRINITE process is a new nitriding and nitrocarburizing method developed by NACHI based on its years of experiences and a low temperature heat treatment carried out in a partially dissociated ammonia atmosphere enriched with the DRINITE liquid. In the features many advantages over the conventional nitriding process by saltbath, simple operation, pollution-free, bright finish of work preces, etc.

Pit Type

|

Model |

Work Space |

Capacity (kg at 570oC) |

|

|

Dia |

Depth |

||

|

EMN-2040 |

500 |

1000 |

270 |

|

EMN-2448 |

600 |

1200 |

340 |