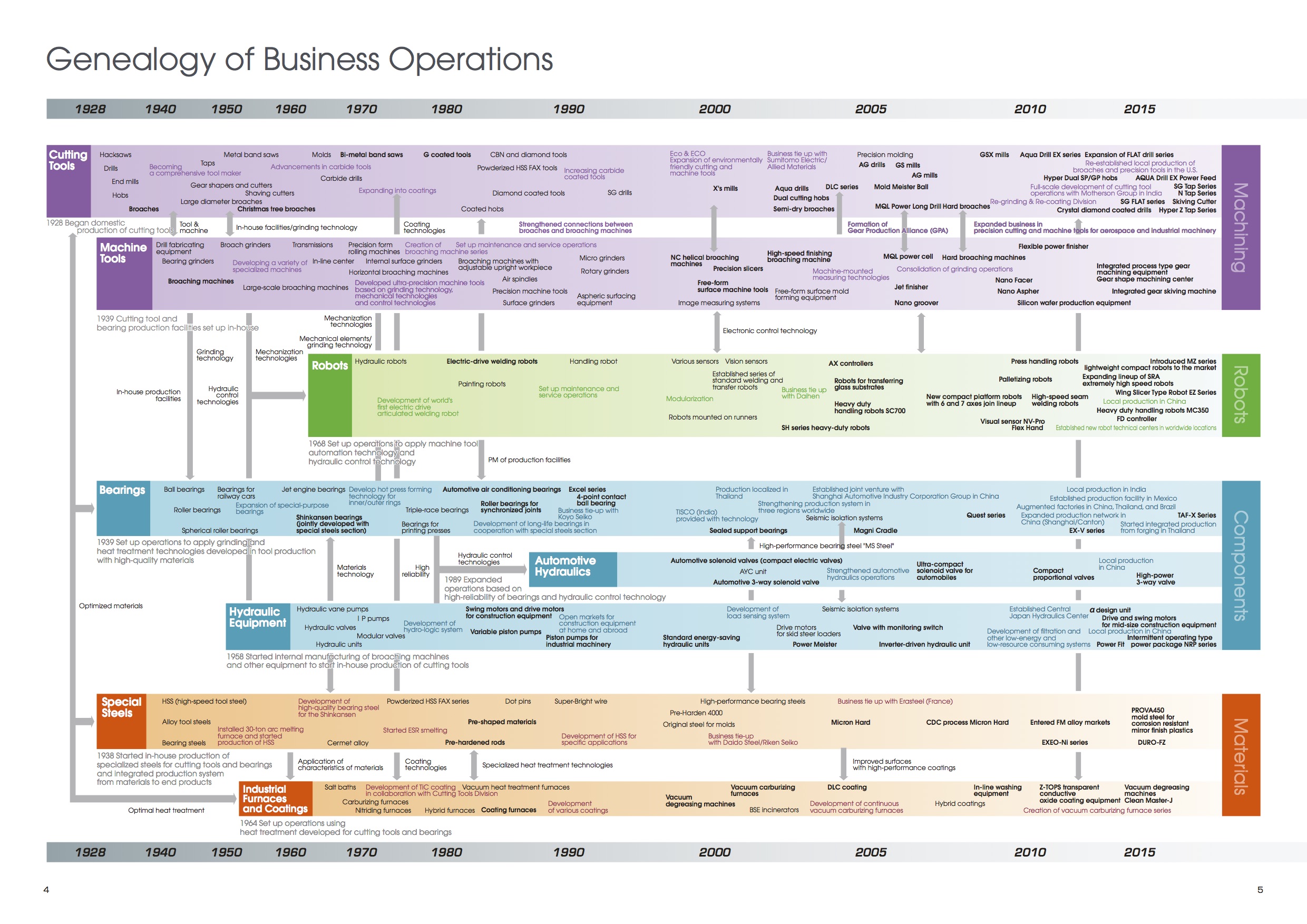

Since 1928 -NACHI-FUJIKOSHI was founded with the express aim of becoming a domestic manufacturer of cutting tools and machine tools in the trend towards industrial modernization. The Company’s business activities expanded greatly in the first 20 years since its founding.

|

Kohki Imura (Born in 1889 in Shimabara, Nagasaki Prefecture) Establishes a company oriented toward technological development. |

| 1928 | FUJIKOSHI STEEL INDUSTRY CO., Ltd. was founded in Toyama City by the founder, Kohki Imura. |

| 1929 |  NACHI hacksaw blades were chosen as a superior example of Japanese manufacturing technology and were personally inspected by the Emperor Showa. NACHI hacksaw blades were chosen as a superior example of Japanese manufacturing technology and were personally inspected by the Emperor Showa.

The NACHI trademark was adopted from the name of the Emperor’s ship. |

| 1934 | The company gained recognition as an all-round domestic manufacturer of precision cutting tools.

installed the latest European and American machinery. |

| 1937 | established FUJIKOSHI Technical High School. |

| 1938 | Higashi-Toyama Steel Mill started operation.

established integrated manufacturing system covering materials through to final production. |

| 1939 | begun production of bearings.

Machine Tools Dept. established to supply own company plants with internally manufactured machinery. |

| 1940 | Business further expanded to 18 plants in Japan and number of employees increased to 36,000.

established FUJIKOSHI Hospital. |

Since 1945 – NACHI-FUJIKOSHI attained the position of a “total machinery manufacturer” as the result of an active management policy during the high economic growth period in the 1950’s to 1960’s

| 1945 |  expanded product line-up to include hand tools, food industry machinery, bicycles, and motorcycles. expanded product line-up to include hand tools, food industry machinery, bicycles, and motorcycles. |

| 1953 | developed Christmas tree type broaches for jet engines. |

| 1955 | begun marketing with large OEM customers in Europe and America. |

| 1958 | begun production of hydraulic equipment. |

| 1962 | Company restructured along divisional lines (cutting tools, bearings, machine tools and special steels).

established NACHI AMERICA INC. |

| 1963 | changed Company name to NACHI-FUJIKOSHI CORP

developed bearings and its materials for the Bullet Train “Shinkansen”. |

Since 1964 – NACHI-FUJIKOSHI is aiming at becoming a mechatronics manufacturer in keeping with technical innovation and internationalization.

| 1964 | begun production of industrial furnaces. |

| 1967 | Office opened in Germany. |

| 1969 | developed hydraulic industrial robots.

established Machine Tool Division and Hydraulic Equipment Division. |

| 1972 | begun local production in Brazil. |

| 1975 | Offices opened in Australia, United Kingdom, Singapore and Canada. |

| 1976 | begun local production in U.S.A. and Spain. |

| 1979 | developed first motor-driven robots for spot welding in the world.

begun local production in Singapore. |

| 1984 | established Robot Division and Precision Machinery Division.

awarded the PM (Productive Maintenance) Prize. |

| 1988 |  opened FUJIKOSHI Guesthouse “Muhenkaku” to commemorate the Company’s 60th anniversary. opened FUJIKOSHI Guesthouse “Muhenkaku” to commemorate the Company’s 60th anniversary.

begun local production in Korea and Taiwan. |

| 1989 | established NACHI TECHNOLOGY INC., U.S.A. |

| 1990 | begun production of handling robots. |

| 1991 | acquired National Broach & Machine Co. (brand name Red Ring).

awarded the Deming Application Prize. |

Since 1993 – NACHI-FUJIKOSHI has been steadily promoting the NACHI Business in keeping with globalization and changes in the industrial structure.

| 1993 | Masamichi Honda was appointed as President.

management restructured due to Japan’s deflationary economic environment and appreciating yen. |

| 1994 | cooperated with Koyo Seiko., Ltd. in the area of bearings. |

| 1997 | obtained ISO 9001 certification in 1995 for each division and overseas plant. |

| 1998 |  Kensuke Imura was appointed as President. Kensuke Imura was appointed as President.

setup new corporate brand mark at the 70th anniversary. established NACHI Techno Square in the Toyama plant. |

| 1999 | set up new management system in keeping with the philosophy “Prospective Selection and Integration”.

changed eight-division structure to three main manufacturing divisions and three strategic divisions. concluded technical assistance agreement with TISCO (India) for the manufacture of bearings. comprehensive business tie-up with Sumitomo Electric Industries, Ltd. in the area of cutting tools. |

| 2000 | expanded overseas supply systems (Thai plant and others) to enhance sales bases.

cooperated with Daido Steel Co., Ltd. in the material field. announced mid-term management plan “NACHI Business Plan 03”. |

| 2001 | built a new factory for broaches, high speed steel wire materials, and hydraulic pumps.

cooperated with Daihen Corporation in the robotic field. obtained ISO14001 Certification. introduced Meister system. |

| 2002 | established Marketing Strategy Headquarters and Development Headquarters.

formed Gear Production Alliance in the gear-processing field. cooperated with Erasteel S.A. (France) in the high speed steels field. introduced performance-based salary system. expanded stock Ownership Plan. |

| 2003 | The 75th anniversary.

built QA Lab, Kohki Hall and Development Office in NACHI-BUSINESS Galaxy. integrated the ultra-precision machining field into machine and cutting tool business. formed a joint venture with Shanghai Automotive Industry Corp. in bearing business. created a mid-term management plan, “Prospect of NACHI Business 2006”. begun recruitment on an as-needed base. |

Since 2004 – NACHI-FUJIKOSHI expanded the production and distribution system both domestically and abroad and uphold the NACHI brand in world markets.

| 2004 | removed Tokyo Head Office to Shiodome, Tokyo.

increased the share capital. established FUJIKOSHI Associé Co., Ltd. to strengthen training. built new bearings factories in the Toyama Plant (Japan), Czech and China. consolidated hydraulic equipment business into the Higashi-Toyama Plant and established a new hydraulic valves factory. divided manufacturing of hydraulic equipment with DAESUNG-NACHI HYDRAULICS CO.,LTD. set up NACHI Material Association. entered into the field of seismic isolator business. |

| 2005 | renewed the Nachi-Fujikoshi Museum and Café Across (2004), and expanded NACHI COMPLEX with NACHI-BUSINESS Galaxy.

designated new brand names for each products group. organized business locations in America, Europe and ASEAN respectively. built a new factory for large-sized robots. launched a new HR project encouraging each employee to improve their skills. |

| 2006 | set up NACHI Major Dealers Meeting.

strengthened the business for industrial machines. established a new broaches factory and a new materials factory. founded a rep.office in India. expanded the engineering business for machining in both domestic and overseas market. expanded FUJIKOSHI Hospital. |

| 2007 | set up International Trade Headquarter, expanded overseas business.

formed a business alliance with Sankyo Tateyama Aluminium, Inc. in magnesium business. built a new gear cutting tools factory, machine parts processing factory, hydraulic motor factory and YAMAGATA factory. established “R&D Material”. developed the business on the industrial machinery sector by releasing the new platform robot. |

| 2008 | set up ASEAN Business Center in Thailand.

built three new factories for precision bearings, bearing heat-treatment, automotive solenoid valves. focused on environmental and energy saving business. expanded the engineering business. integrated production of bearings in Europe into Czech. built Nachi-Fujikoshi Selva introduced anti-takeover measures. |

| 2009 | Hiroo Honma was appointed as President.

developed new management framework. started up the internal control system. expanded the bearing factories in Thailand and Brazil. assigned a representative in Turkey and expanded the business in emerging countries. established Central Japan Hydraulic Center to penetrate the energy and infrastructure markets. built NACHI Logistics Center. integrated production of tools in the US into Indiana. |

| 2010 | shifted dynamically to emerging countries. set up Robot Business Center in China.

enhanced the structure for production, sales and services in China, ASEAN, India and South America. enhanced the structure for development. introduced the palletizing robots and penetrated the distribution infrastructure markets. developed transparent conductive oxide coater and high speed seam welding robots together with the alliance companies. |

Since 2011 – Aim for long-term growth with new markets, business areas and management structure in this era of change.

| 2011 | announced 2020 long-term vision and 2013 midterm business plan. revised corporate philosophy, corporate mission, and operating principles. introduced executive management system.

revamped and strengthened manufacturing operations from four to eight divisions according to products. established production network in India, expanded full-scale into machinery production business. global simultaneous launch of extremely high speed spot welding robot in Japan and abroad. |

| 2012 | established production network as the core of operations for China in jiangsu Zhangjiayang China.

bolstered sales, production, and procurement systems in China, and advanced entrance into automotive and industrial machinery markets. established bearing production facilities in India, accelerated entrance into industrial machinery and automotive markets, introduced integrated process type gear machining equipment to the market and entered industrial machinery market. |

| 2013 | fully started production of tools, hydraulics, automotive hydraulics, and robots in China, expanded lineup of high-performance drills and enlarged market share, world’s fastest lightweight compact robot MZ07 released simultaneously around the world. |

| 2014 | established 2016 midterm business plan as a milestone in 2020 long-term vision.

established Production Technology Headquarters to develop overseas factories and integrate production technologies. established Sales Strategies Headquarters to plan and promote sales strategies globally. re-established local production of broaches and precision tools in the U.S. |

| 2015 | established production of round tools, such as carbide drills, in the U.S.

established new bearing production center in Mexico. |

| 2016 | newly established the forging of bearings and turning factories in Thailand to achieve an integrated production system. |