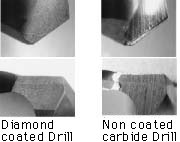

Diamond coating

- 100% pure diamond coating.

Suitable for nonferrous metals,nonmetals

Long tool life

- The tool life is 10 times of conventional carbide drill in drilling high silicon aluminum

Precision

- It is possible to acquire excellent surface roughness

Series

- Diamond Coated Drill

- Diamond Coated FF Drill

Mechanism of Diamond Coating

|

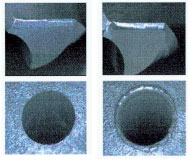

Growth Process of Diamond Film

|

|

Growth process of Diamond film is called as Volmer-Weber type and generally increase its thickness by birth and growth of core repeatedly. |

100% pure diamond coatingApplicable on unique cutting edgeApplicable on Micro tool |

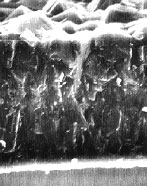

Cross section photo of diamond film |

Work materials of Diamond Coated tools

|

Comparison of Drilling accuracy

|

||||||||||||||||||

|

||||||||||||||||||

Performance of drilling High silicone

|

|

||||||||||||||

Performance of drilling MMC

|

|

||||||||||||||

Examples

| Drill Diameter | Material | Comparison of Tool Life | Drilling Condition | |||||||

| Convertional Carbide Drill | Diamond-Coated Drill | |||||||||

| 2.5 | ADC12 (Al-12%SiAlloy) |

20,000 Holes |

258,000 Holes |

|

||||||

| 6.0 | A390 (Al-17%SiAlloy) |

100 Holes | 2,300 Holes |

|

||||||

| 3.0 | GFRP | 3,000 Holes | 30,000 Holes |

|

||||||

| 1.5 | Pre-Sintered WC-Ceramics |

100 Holes | 14,000 Holes |

|

||||||

| 2.0 | Pre-Sintered Al2O3-Ceramics |

Half Day to 3 days |

More than 3 months |

|

||||||