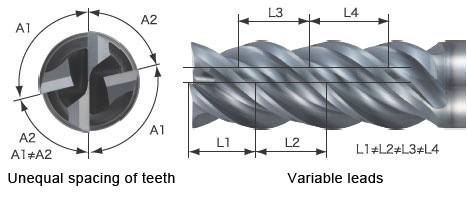

Endmill with unequal tooth spacing and variable leads

For titanium alloy and SUS and for steels

GSX II coating

|

Unequal spacing of teeth · Variable leads

Reduce vibration and realize high quality milling by adapting unequal index and lead design.

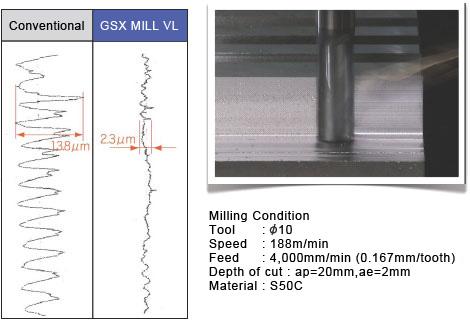

Comparison of vibration

Applicable to wide range of materials by two series

GSX-II Coating

Excellent heat resistance

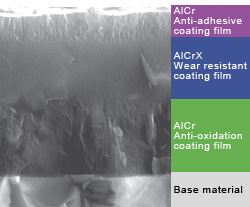

Multi layer structure

Crystal structure

|

|

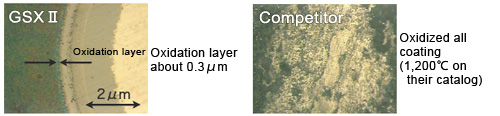

Evaluation of oxidation resistance

Status of coating films after keeping with 1,100°C in the air after 1 hour.

GSX MILL VL Series

GSX MILL VL Anti-Vibration Effect (Movie)

|

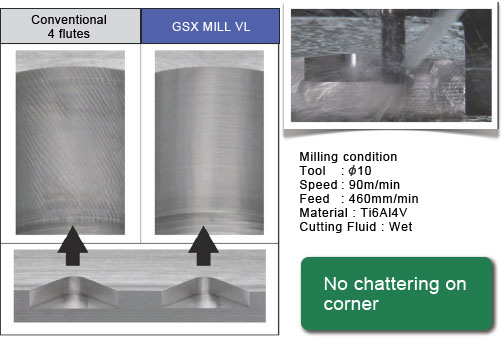

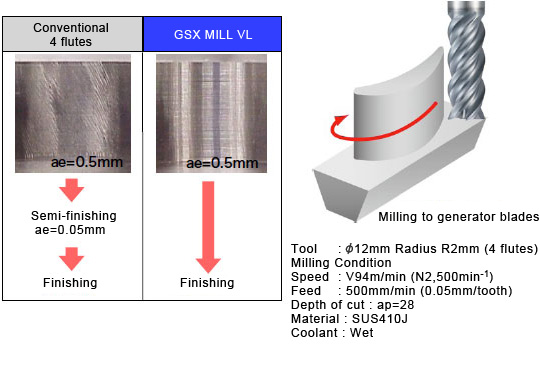

Conventional 4 Flutes End mill |

GSX MILL VL |

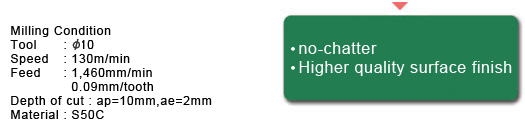

Comparison of surface roughness

Surface roughness comparison of milling on Titanium alloys

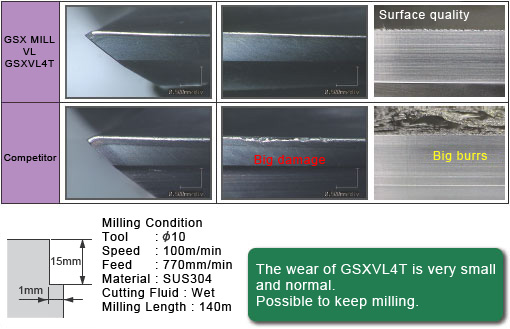

Wear comparison after 140m milling of stainless steels (SUS304)

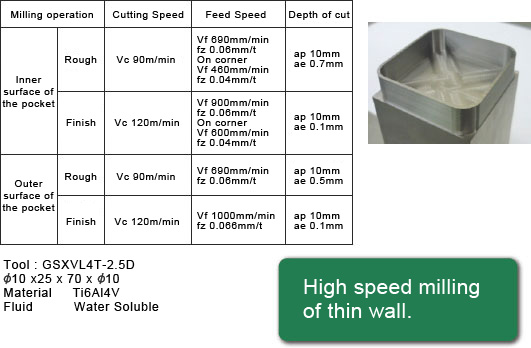

Application example of pocket thin-wall milling of Titanium Alloys

Reduction Process in SUS410J

Catalog Download

![]() Catalog No.2285-7 GSX MILL VL series (20 pages/2,114KB)

Catalog No.2285-7 GSX MILL VL series (20 pages/2,114KB)

GSX MILL VL series