Nachi America’s Cutting Tool Division produces drills, endmills and taps designed to meet and exceed the exacting requirements of the industry’s highest-precision machine tools. Nachi has long been a pioneer not only in tool design but in coatings that add durability and extend cutting life. Our tools are built to perform with precision and provide our customers with efficient, cost-effective solutions.

INDUSTRY RESOURCES

ISA is the product of a consolidation between the Industrial Supply Manufacturers Association (ISMA) and the Industrial Distribution Association (I.D.A.). All active members of both ISMA or I.D.A have now been rolled over into ISA.

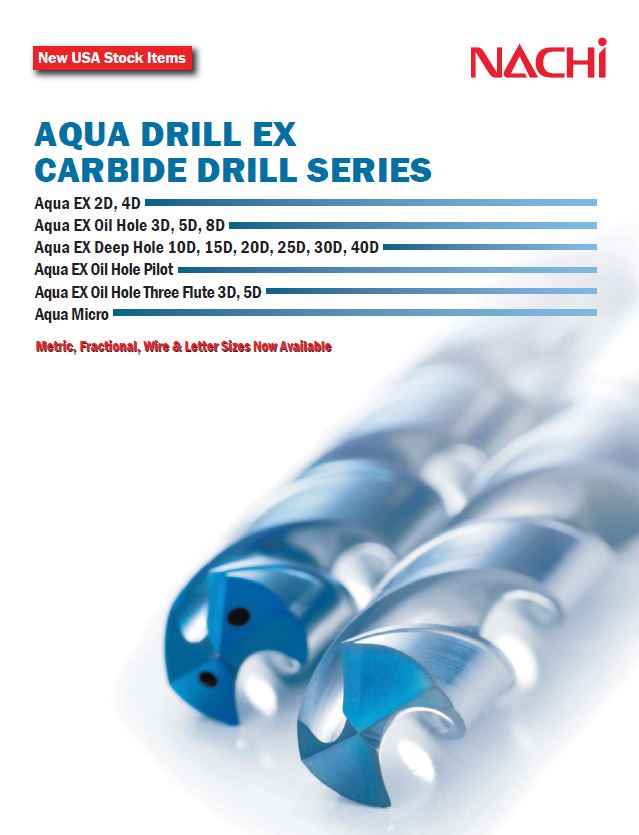

- Adopt the optimized cutting edge and flue geometry to improve the reduction of cutting resistance and chip evacuation drastically.

- Realize high accuracy and longer tool life in ultra-high-speed drilling in machining center or turning machine where chip jamming is easy to occur

Capable of high-accuracy drilling up to a depth of 5D using external cutting fluid

- Achieves high-accuracy drilling with a 3-flute design that achieves excellent cutting balance

- Optimized flute geometry and cutting-edge design enable stable drilling

High-efficiency drill capable of drilling hardened steels of 50HRC or more

- Cutting-edge design with enhanced stiffness delivers both excellent cutting performance and strength, enabling high-efficiency drilling of hard materials (60HRC)

- AQUA EX coating enhances resistance to heat and wear for a longer tool life

Indexable drill suited to high-accuracy, high performance drilling of large-diameter holes

- Features integrated inserts for well-balanced, accurate cutting

- V-shaped mounting facilitates attachment and achieves high accuracy and stiffness

- Suited to a wide range of work materials while ensuring a long tool life

- 1.5D, 3D, 5D, 8D, and a flat insert available in Ø14.0~32.0

High-efficiency drill for drilling small-diameter holes

- Drill diameters of Ø1.0-2.9 available

- Supports drilling depth of 5D, 10D, 15D, and 20D

- AQDEXOHPLT series for guide hole drilling released at the same time

High-accuracy, high performance 3-flute drill with a lubrication hole

- Enables high-accuracy drilling with a 3-flute design that achieves excellent cutting balance and reamerless processing

- Fitted with a lubricating hole, this drill is capable of high-speed, high-feed drilling up to a depth of 10D. Capable of drilling stainless steels

- 3D, 5D, and 10D available in Ø3.0-16.0, with a standard 227 sizes offered for each series

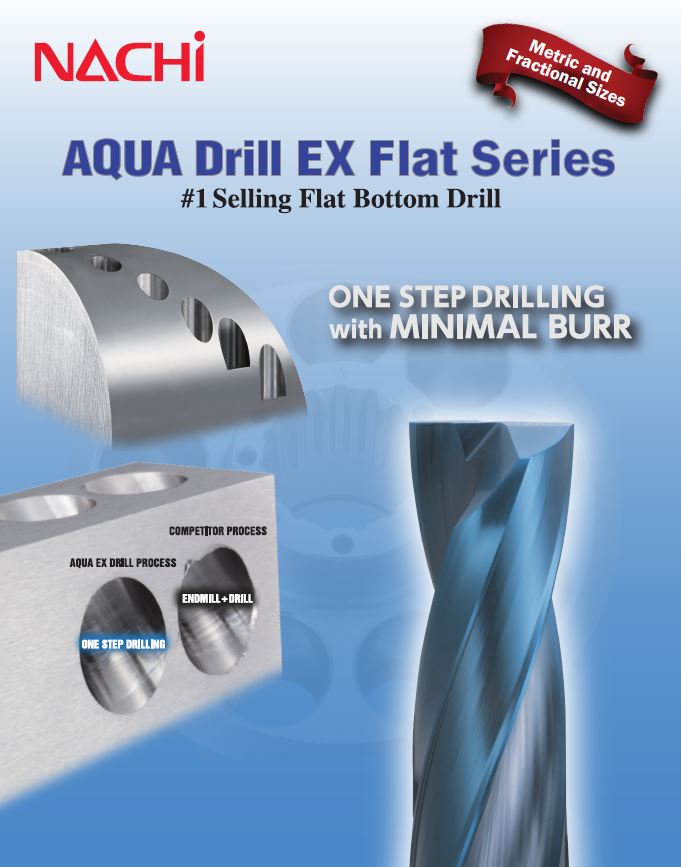

Absolutely flat drill face

- Drill for counter boring has great performance.

- Drilling efficiency improvement due to reduced processing time.

- Better heat and wear resistance from Aqua EX coating.

High-efficiency deep-hole drill with a lubrication hole

- Capable of 30D deep hole, non-step drilling

- Long tool life even with deep-hole drilling of stainless steels

- Available in 5 flute lengths from 10D to 30D

- AQUA Drill EX Oil-Hole Pilot is ideal for guide hole drilling

Handles everything from centering to chamfering and high-speed-V-groove cutting, and ensures a prolonged tool life

- Firmly engages the surface for high positioning accuracy

- Sharp cutting edge allows for a clean machined surface

- Handles everything from centering to chamfering and V-groove cutting

Regular and long-shank types added to the FLAT series

- Regular type capable of flat drilling up to a depth of 4D

- Long shank type capable of flat drilling up to a depth of 2D with a projection length of 10D

- Added to the series to expand the applications of flat drilling

Oil-Hole type added to the FLAT drill series

- Oil-hole drill (3D) that increases drilling efficiency and supports stainless steels

- Oil-hole drill (5D) that achieves highly efficient flat drilling up to a depth of 5D

- Added to the series to expand applicable work materials and achieve high efficiency

Super heat-resistant drill for difficult-to-machine materials

- Achieves both wear resistance and chipping resistance by using cemented carbide, which is suited to heat-resistant alloys

- Guarantees a long tool life by adopting AQUA EX coating, which offers excellent resistance to heat and wear, as well as high lubricating performance

Super heat-resistant drill for difficult-to-machine materials

- Achieves both wear resistance and chipping resistance by using cemented carbide, which is suited to heat-resistant alloys

- Guarantees a long tool life by adopting AQUA EX coating, which offers excellent resistance to heat and wear, as well as high lubricating performance

Carbide drill for high-efficiency drilling of a wide range of materials, from general steel to heat-resistant alloys

- Achieves high-speed, high-efficiency machining

- Long tool life with stainless steel

- Available in 3 flute lengths (3D, 5D, and 8D) with a standard 393 sizes offered

Enables stable, high-efficiency drilling, from low/ medium speeds to high speeds

- New cutting edge design adopted to dramatically improve chip evacuation

- Reduces cutting resistance to enable stable drilling with small machines

- Achieves a long tool life with enhanced resistance to heat and wear as well as lubricating performance with AQUA EX coating

- Stub (3D) and regular sizes (5D) available in a series

Indexable drill for stable drilling on angled surfaces

- Optimal balance of the central insert and peripheral insert minimizes fluctuation of cutting resistance for stable drilling

- 4-cornered insert for superior economic efficiency

- 3 types of chip breaker and 2 types of material are offered to cover a wide range of work materials and applications

Enables ultra-high-speed wet drilling and dry drilling

- Achieves wet drilling at 3 times the efficiency of competitor products

- Equivalent tool life for dry and wet drilling

- Enables stable drilling with a unique cutting edge design and AQUA coating, which demonstrates excellent lubricating performance

- Series: Stub, Regular

High reliability and stability in drilling small-diameter holes

- Prevents breakage by adopting a high-stiffness design and cemented carbide, which is suited to drilling small-diameter holes

- Reduces cutting resistance through peripheral clearance and thinning

- Delivers outstanding performance with high-speed drilling by applying AQUA coating

- Enables high chucking performance by adopting a 3-mm shank across the board

Capable of high-accuracy drilling as well as reamerless processing

- Achieves high-accuracy drilling with a 3-flute design that achieves excellent cutting balance

- Compatible with both wet and dry drilling

- Enables stable drilling with a unique cutting edge design and AQUA coating, which demonstrates excellent lubricating performance

Capable of drilling hardened steels ( 50-70 HRC)

- Supports high-efficiency drilling of steels with a hardness of 50-70HRC

- Features optimal cemented carbide and AQUA coating for a stable drilling tool life

- Prevents breakage with a high-stiffness design

- Adopts an end-mill shank

Achieves dry drilling of aluminium alloys

- Coated with DLC, which exhibits high hardness, a low friction coefficient, and excellent wear resistance

- Features DLC coating and a unique flute geometry to enable non-step drilling to a depth of 5D

- Enables high-accuracy drilling by adopting an end-mill shank

- Series: DLC Micro Drills, DLC Drill Regular

Achieves long-life drilling of nonferrous metals

- 100% pure diamond coating

- Suitable for aluminum alloys and other nonferrous metals

- Demonstrates a tool life over 10 times that of non-coated drills in drilling aluminum alloys

- Series :Diamond Coated Drill, Diamond Coated FF Drill

Coated carbide drill that achieves deep-hole non-step drilling

- Performance of non-step drilling to a depth of L/D20

- 5X drilling efficiency

- Stable tool life

- New style of innovative Taps taken full advantage of NACHI Technologies.

- Realize longer tool life than coated taps at low and middle speed.

In stainless steel processing, this tap exerts maximize the performance of Hyper Z series!

- Analyze the flow of chips and adopt the optimum cutting edge and groove shape specialized for stainless steel.

- NACHI original surface treatment keeps the sharpness of the cutting edge and improves wear resistance.

With high flexibility, superior performance can exert on cutting various materials, machines, and wide range of cutting conditions

- The longest tool life by high grade powder HSS and SG coat

- Realized stable cutting screw threads, and the high rigidity and chips ejection can coexist by optimizing the edge and flute shape

- Short Chamfer type of SG Spiral Taps

- To secure the effective length of screw to the maximum by tapping blind holes of thin plate

- High efficiency drilling and tapping in combination with AQUA Drill EX Flat

- Excellent taps for blind holes on titanium alloy material

- Long tool life and stable tapping by less chip welding and jamming

To exhibit excellent performance for through holes

- To be consistent rigidity and chips ejection by clean cutting spiral point and optimizing flute shape

- Stable cutting screw threads by excellent wear and chipping resistance

High flexibility tap has good cost performance

- Suitable for characteristic of cutting screw threads, high flexibilith tap is long tool life by high vanadium HSS

- Stable cutting screw threads by high rigidity design

Carbide roughing end mill ideally suited to high-efficiency pre-finish machining

- End mill featuring unequal spacing of teeth and variable leads to suppress chattering vibration

Pre-finish model added to the GSX MILL VL series - Optimizes cutting-edge design and nick shape for enhanced chipping resistance and high-efficiency machining

Carbide end mill ideally suited to machining high-hardness materials

- Controls chattering with unequal spacing of teeth and variable leads to achieve high-quality machining

- Improves chip evacuation and stiffness with flute geometry optimized for high-hardness materials

- Features heat-resistant carbide materials and GSX II coating for a longer tool life

Endmill with unequal tooth spacing and variable leads to suppress chattering

- It specializes for Titanium alloy and for Carbon steels and the series is made.

- GSX II coating for greater heat and wear resistance, plus anti-adhesion properties.

Perfect for vertical wall milling up to 5D height

- Applications are expanded with VL’s longer shank that suppresses chattering.

- High-speed milling is realized for raw materials, titanium alloy, and heat-resistant alloy.

- GSX II coating with superior heat, wear and adhesion resistance to achieve long tool life.

- Additional release of the radius model.

Unequal tooth spacing and variable leads that suppress chattering using six blades

- High-speed milling is realized for raw materials, titanium alloy, and heat-resistant alloy.

- GSX II coating with superior heat, wear and adhesion resistance to achieve long tool life.

- Additional release of the radius model.

Ball end mill that covers from common applications to high-speed applications

- Smooth streamlined ball nose-shaped edge improves chip removal.

- High-speed milling is possible for raw materials, stainless steel, and hardened steels.

- GSX II coating with superior heat, wear and adhesion resistance to achieve long tool life.

Designed for high-efficiency pre-finish machining

- Optimized cutting edge design and nick shape for greater chipping resistance

- GSX coating offers enhanced resistance to wear and heat, ensuring a longer tool life

Highly versatile end mill suitable for any application

- Micrograin carbide, which offers high transverse rupture strength and superior thermal shock resistance, ensures greater reliability in wet milling of soft materials

- Enhanced resistance to wear and heat provided by the new GSX coating ensures greater reliability and a longer tool life with a wide range of work materials

High efficiency machining and excellent machined surface quality

- New indexable endmill for high efficiency machining and excellent machined surface quality.

- Wide application range by 3 types of inserts and 5 kinds of inset grades.

Super high speed milling

- Newly developed ultra aluminum rich Al-Ti-Cr multi-layered “GS Hard Coat” allows super high speed milling up to 800m/min.

- Unique geometry improves chip removal and tool rigidity.

- Improved durability due to new ultrafine particle, cemented carbide.

HSM in wide range

Wide range of High Speed Milling from carbon steel to hardened steel – Thanks for the best combination with Multi-layered TiAlN coating film and tough carbide substrate.

Easy chip control

High speed grooving, and drilling by 4 flutes mill

Thanks for NACHI unique flute geometry.

Ridged and tough

Unique flute geometry and wide land on the cutting edge – Tough cutting edge bring extreme high milling speed and excellent finishing surface.

Series

X’s mill Geo L9322

X’s mill Geo Radius L9324

For milling of deep groove

It is possible to mill deep groove due to adoption

neck or smaller shank dia.

Rigid and tough

Unique flute geometry and wide land on the cutting edge – Tough cutting edge bring extreme high milling speed and excellent finishing surface.

Long tool life

Wide range of High Speed Milling from carbon steel to hardened steel – Thanks for the best combination with Multi-layered TiAlN coating film and tough carbide substrate.

Drilling – Groove milling

By the adoption of the end teeth which has excellent chip flow and well balanced three flutes, efficiency drilling is possible. A basic form is equal to XAfs mill GEO and high helix angle produce a fine finishing.

Long tool life

A long tool life is realized by the excellent X’s coat.

Excellent sharpness around the ball nose edge by new concept Geometry.

Smooth connection between ball nose end cutting edge and peripheral cutting edge.

Compatibility of strength and sharpness

by the optimal chisel shape.

Long tool life by the good combination of high wear-resistant carbide as well as X’s coating

High speed and long tool life

High speed and long tool life is realized, because of using tough tool material & coating for small size end mill.

High stiffness

Precise milling is realized without vibration, because of adoption thick web, unique geometry of flute,and new chisel geometry.

Adoption of 6mm shank

Tolerance of É”6 shank is within 5É m.

Suitable for precise milling due to chucking accuracy is increase.

Series

X’s mill GEO Micro Ball LIST9332

X’s mill GEO Micro Ball long neck LIST9334

High speed milling

Efficiency beyond the speed 500m/min dry milling.

Sharpness

Sharpness is increase due to adoption high helix angle and adequate cutting face angle.

High efficiency and precise milling

Realize more efficiency and better finishing due to adoption multi flutes.

For hardened steel

It is possible to mill work material of over 60HRC.

Delivery time of mold is reduced

Hard Ball can proceed direct milling of hardened steels.

Shortening delivery time and reduce cost.

Precise milling

Efficiency is increase 30%,and acquire excellent surface roughness.

Series

X’s mill HARD Regular LIST9286

X’s mill HARD Ball LIST9284

X’s mill HARD Long LIST9288

Long tool life

Efficiency processing of stainless steels,Nickel alloys.

Adhesion resistance is increase due to adequate cutting face angle and X’s coat.

Precise milling

Acquire the superior roughness of machined surface due to high helix angle and sharpened cutting edge.

High stiffness

It is suitable for efficient processing due to high stiffness which is by thick web.

Wavy shape

Adapted new Wavy inserts’ form, high speed milling is coming by its Wavy form, reduced milling force and tough cutting edge.

Long tool life

Combination with Multi-layered X’s coating film and fine grade carbide, this is reliable and long tool life cutter in HSM field.

Wide application

For Carbon steel, Alloy steel, cast Iron and Stainless steel, and for any kind of milling operation.

Series

X’s mill Wavy XSWEM type LIST9326

XSWMM type LIST9336

X’s mill Wavy Ball LIST9328

Multi-function

Enables grooving, shoulder milling, ramping, helical milling, pocket milling and drilling with a single end mill.

Wavy cutting blade

Uses the same chip as that for the XSWEM model. Employs a unique wavy chip for high-speed, high-efficiency cutting.

Wide application

Can be used on a wide range of materials including ordinary steel, alloy steel, stainless steel, and cast iron.

Series

Shank type (2000 and 3000 type)

Wavy cutting edge

Employs unique wavy chip and strong whirl-stop mechanism to provide high-speed, high-efficiency cutting.

Long tool life

X’s coating applied to ultra-fine cemented carbide with high chipping resistance for stability and long life.

Wide application

Used for rough or medium finish cutting (contour line process and tridimensional copying) for ordinary steel, alloy steel, die steel and cast iron.

Series

3 types: S, M and L

Dry milling of Aluminum

DLC (diamond-like carbon) is an amorphous material with high hardness and low friction rate, and has similar character of Diamond.

Application for milling in Aluminum Ultra high speed cutting in DRY!

Excellent surface roughness

Dry milling is possible by high rake design, and DLC coating on a lapping rake face.

Surface roughness of wet milling is realized by dry milling.

Applicable end mill

X’s Mill Wavy 2000 and 3000 models

X’s Mill Wavy Multi-function types 2000 and 3000

Dry milling of Aluminum

DLC (Diamond Like Carbon) is an amorphous material with high hardness and low friction rate,and has similar character of Diamond.

Application for milling in Aluminum Ultra high speed cutting in DRY !

Excellent chip evacuation

Trouble free drilling by unique flute geometry Stable & extra long tool life is realized by DLC film & its unique flute.

Dry milling of Aluminum

DLC(Diamond Like Carbon) is an amorphous material with high hardness and low friction rate,and has similar character of Diamond.

Application for milling in Aluminum Ultra high speed cutting in DRY.

Excellent chip evacuation

Trouble free milling by unique flute geometry Stable & extra long tool life is realized b DL film & its unique flute.

High Accuracy on Corner Radius

The accuracy on Corner Radius is excellent .

Diamond coating

100% pure diamond coating.

Suitable for nonferrous metals,nonmetals.

Long tool life

The tool life is 10 times of conventional carbide End mill in milling high silicon aluminum.

Precision

It is possible to acquire excellent surface roughness.

Series

Diamond Coated End Mill Two Flutes

Diamond Coated Stub End Mill

Diamond Coated Ball End Mill

For the production method of gears, there are various ways such as cutting, forming and forging. Our company offers gear cutting tools with latest designing technology and manufacturing technology, targeting faster and more precise manufacturing of gears.

Achieved dry cutting and longer life of gear cutting.

For high-speed dry and wet hobbing

- SP hob: Capable of high-speed dry hobbing at 300 m/min

Achieves a long tool life with high-hardness materials - GP hob: Suitable for dry and wet hobbing in any condition

Great performance without coating after regrinding

- Applicable for wet and dry hobbing.

- Long service life due to re-grinding specifications without coating on cutting face.

Dual Cut Hob

Both dry hobbing, which solve environmental problem and conventional wet hobbing are available.

For Dry and Wet Hobbing

In dry hobbing, cutting speed can be changed faster than that in conventional wet cutting, and tool life is longer as well.

Long Tool Life in Wet Hobbing

Even if wet hobbing, higher cutting speed and longer tool life are achieved.

We make proposals for cutter designs and processing technologies tailored to gear dimensions

- Design proposals tailored for the gear dimensions and shapes

- Surface treatment tailored to skiving processing

- Select the optimum tool materials

Enhances the accuracy of internal gears and enables modification of tooth profiles

- Achieves internal gear shaving

- Shortens the time required to replace the work piece with automatic engagement of work piece and cutter and with special loading equipment

- Applicable for crowning and taper machining

- Contributes to noise reduction in planetary gear mechanism

Ultrahigh Speed in Dry Hobbing

More than 300m/min in cutting speed is available.

High Efficiency

3 times higher than that of HSS Hob.

Long Tool Life

Over 10 times longer than that of HSS Hob.

Click on a catalog to download it to your hard drive.

Click on a brochure to download it to your hard drive.